|

NP - Self Clinching Fasteners - Broaching Panel Fasteners

|

|

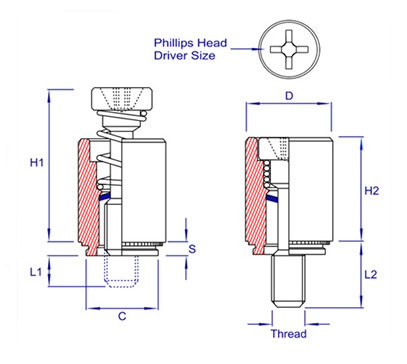

Self Clinching Phillips Head Panel Fasteners provide a captivated spring loaded screw for use in thin sheet metal where subsequent access is required.

Self Clinching Phillips Head Panel Fasteners provide a captivated spring loaded screw for use in thin sheet metal where subsequent access is required.

They reduce loose components and so reduce the risk of loose hardware being lost or falling out and damaging internal components. Actuation can be by tool or hand.

Like all self clinching fasteners they are installed using a parallel squeezing action so require access to both sides of the panel for initial installation.

Available in Steel and Stainless Steel in thread sizes M3 - M5 (M6 available to order) in a range of screw lengths.

Please check for availability before specifying.

|

|

|

|

Thread

& Pitch |

Screw

Code |

Hole

Size

+ 0.1 |

Minimum

Panel

Thickness |

S

Max |

C

Max |

D

± 0.25 |

L1

± 0.64 |

L2

± 0.4 |

H1

± 1.5 |

H2

Max |

Driver

Size |

Min C/L

to Edge |

M3 x 0.5 |

40 |

6.73 |

1.53 |

1.53 |

6.7 1 |

7.9 2 |

0 |

6.4 |

13.72 |

9.40 |

#1 |

6.35 |

62 |

3.2 |

9.5 |

M4 x 0.7 |

50 |

7.92 |

1.53 |

1.53 |

7.90 |

9.53 |

0 |

7.9 |

17.91 |

12.19 |

#2 |

7.87 |

72 |

3.2 |

11.1 |

94 |

6.4 |

14.3 |

M5 x 0.8 |

50 |

8.74 |

1.53 |

1.53 |

8.72 |

10.31 |

0 |

7.9 |

17.91 |

12.45 |

#2 |

8.63 |

72 |

3.2 |

11.1 |

94 |

6.4 |

14.3 |

M6 x 1.0 |

60 |

10.49 |

1.53 |

1.53 |

10.47 |

11.89 |

0 |

9.5 |

22.99 |

15.75 |

#3 |

9.65 |

82 |

3.2 |

12.7 |

04 |

6.4 |

15.9 |

Please check availability before specifying.

Materials |

Finishes |

Carbon Steel |

Bright Nickel over Copper Flash (CN) |

|

The following installation panel material hardness limitations

apply when installing Self Clinching Phillips Head Panel

Fasteners. Steel Panel Fasteners: 60HRB Max

|

Part Number Examples |

Type | Thread | Screw Code | Finish

i.e. : NPFP-M5-50-CN

(Phillips Head Panel Fastener-M5-Screw Code 50

-Steel-Copper Nickel)

|

|

|

|

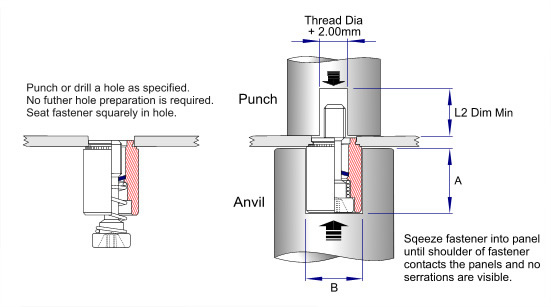

Installation Guide

|

|

|

Thread

Size |

Screw

Length

Code |

L2

Dim Min |

A ± 0.05 |

B ± 0.05 |

M3 |

40 |

6.4 |

8.76 |

8.2 |

62 |

9.5 |

M4 |

50 |

7.9 |

11.05 |

9.8 |

72 |

11.1 |

94 |

14.3 |

M5 |

50 |

7.9 |

11.05 |

10.69 |

72 |

11.1 |

94 |

14.3 |

M6 |

60 |

9.5 |

14.35 |

12.29 |

82 |

12.7 |

94 |

15.9 |

First punch or drill the correct size hole. DO NOT deburr the hole prior to installation as this will remove material required during the clinching process. It is preferable to install the fastener from the side of the panel with the burring or blow through.

Place the fastener in the hole like in the diagram above making sure the part is seated squarely.

Apply a parallel squeezing force until the fastener is seated against the panel with no serrations visible. Do not over squeeze the fastener into the panel as this will result in the fastener being damaged.

When installing Self Clinching fasteners, please pay attention to the minimum hole centerline to edge and parent material hardness limitations.

For special applications or if you are unsure of any aspect about the usage or installation of this fastener, give our sales office a call and we will do our best to offer you a solution or give advice on your application.

|

|

|

Performance Data

|

Thread |

Test Panel Material |

Aluminum |

Steel |

Installation (kN) |

Pushout (N) |

Installation (kN) |

Pushout (N) |

M3 |

10.7 |

1068 |

13.3 |

1334 |

M4 |

12.9 |

1334 |

16.9 |

1779 |

M5 |

13.3 |

1779 |

17.8 |

2224 |

M6 |

15.6 |

1779 |

22.2 |

2669 |

The above data is based on average values obtained in a test environment. Variations in hole size, panel material and installation will effect performance. It is recommended that you carry out your own performance tests in the actual application. Contact our sales department who will be happy to supply samples free of charge.

|

|

|

İndir

Katalog - Broşür

|